International leaders are calling for a circular economy without waste that is all about reusable raw materials. This is because the current non-circular production and use of e.g. clothing has negative impacts on people and the environment: the textile industry is known for its high water consumption, large amounts of waste and high CO2 emissions. Discarded clothing ends up for the most part in residual waste to be eventually incinerated. Both the economic and sustainable opportunities of the circular economy are therefore enormous in the textile sector.

Many interests are at stake in the textile industry. Therefore, improving the supply chain is a major challenge: Every link in this chain leaves its mark. This can only be changed by bringing together individual actors. This is where CWS comes in: In a pilot project, CWS Nederlands and other Dutch companies from the entire textile value chain (led by Avans Hogeschool and MVO Netherlands) are working with Indian cotton companies to develop a closed raw material chain for the cultivation, processing, use and recycling of cotton. The idea is to use cotton fibres that can be produced regeneratively and recycled several times to preserve existing properties and create added value. The overall goal is to return the fibres as raw material to a new chain.

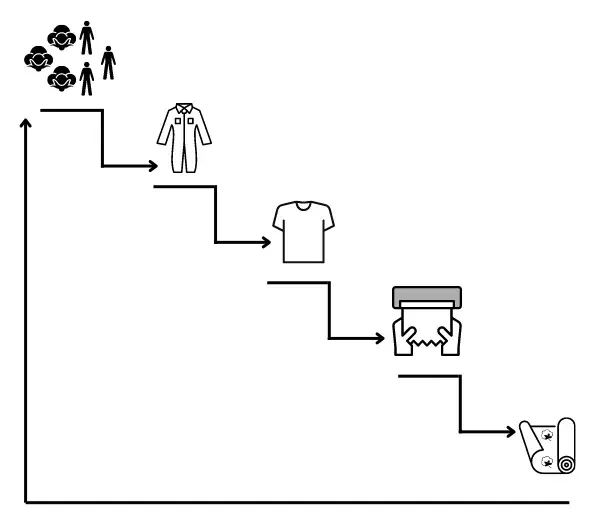

The role of CWS in this cascade is as follows: After the use phase of the original product - e.g. workwear - comes to an end, the cotton fibres it contains are recycled into further textiles such as T-shirts. These in turn then form the raw material for hygiene products, such as CWS fabric towel rolls, after the use phase. At the end of their useful life, these fabric towel rolls are further processed into biodegradable plant protection fleece in order to return them to the agricultural economy and the origin of the plant. Thus, the complete circle has been closed and the fibres could be put to maximum use.

However, a circular model is only possible if all parties involved work closely together and no one is disadvantaged. The aforementioned project focuses in particular on researching the technical feasibility of recycling cotton fibres and developing collaborative business models.