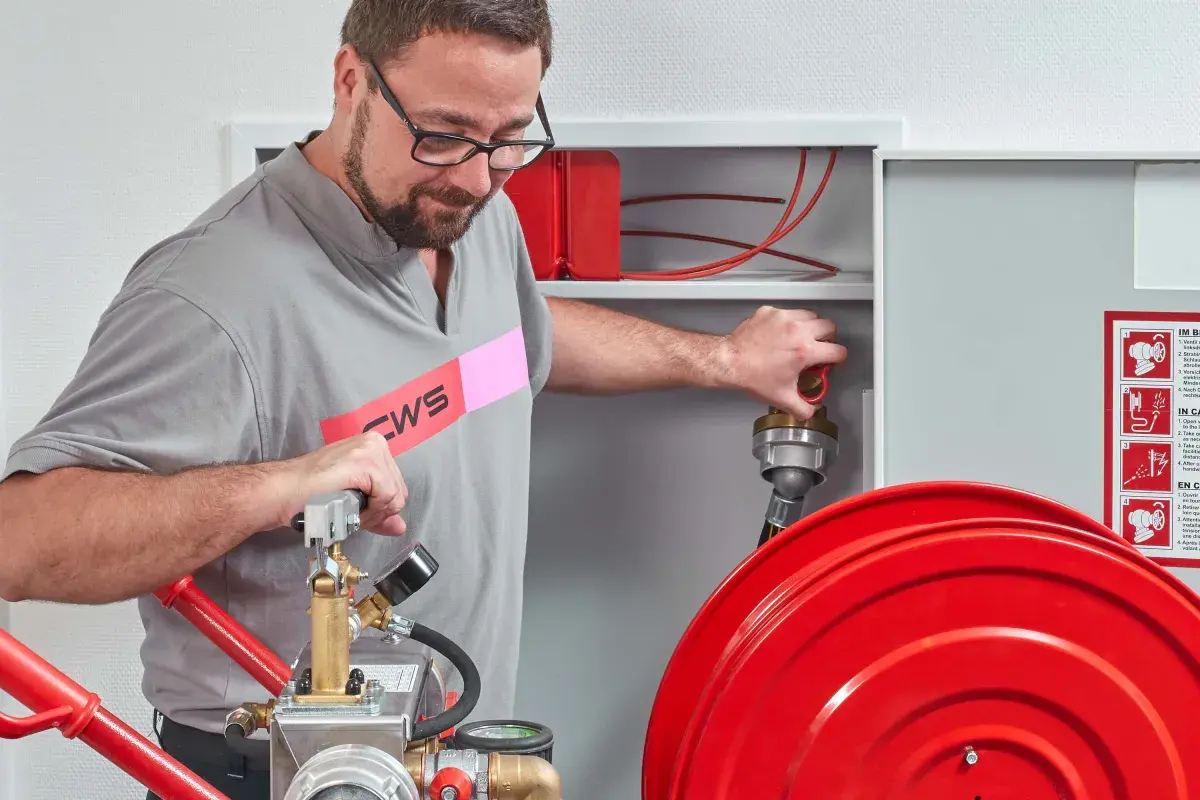

Water march during hydrant maintenance

Wall hydrants are used to fight incipient fires. They are designed so that both laymen and firefighters can use them to extinguish fires. The maintenance of wall hydrants is mandatory. But how can the functionality be tested without putting the building under water? We give you an overview of essential specifications, deadlines and procedures.

When to use wall hydrants

Wall hydrants are basically used for initial fire fighting. There are two types:

- Type S wall hydrant: S stands for self-help. It can be operated by anyone without special prior knowledge due to the low water pressure.

- Wall hydrant type F: F stands for fire department. On the one hand, the fire department can extinguish a fire with the existing hose on the reel, on the other hand, they can also connect an additional hose. Wall hydrant type F can also be used by specially instructed persons, for example company fire protection assistants.

Extinguishing water supply from wall hydrants

Wall hydrants obtain firefighting water with the help of firefighting water supply systems. These extinguishing water supply systems are often located in the basement or at ground level in a building and are either connected to the public water network or are supplied with sufficient extinguishing water by a storage tank filled with water. The extinguishing water system has special pumps that ensure that sufficient extinguishing water reaches the wall hydrant even on the top floor.

Maintenance intervals of wall hydrants

Wall hydrants where the lines are constantly filled with water are serviced at least annually. Wall hydrants with dry risers must be maintained every 2 years. The basic principles are DIN EN 671-3 and DIN 14462. In addition, the manufacturer's specifications and the state of the art must be observed. The following is inspected:

- Accessibility

- Labeling

- Operating instructions

- Damage

- Fixation of the wall hydrant cabinet and the reel support arms

- Faultless opening of the doors

- Smooth operation of the extraction valves

- Other accessories

The essential steps in maintenance

- Unroll the hose completely and pressurize it with the existing operating pressure

- Check the hose for damage and tightness

- Rest and flow pressure measurement at each tapping valve

- Checking the jet pipes / sprayers under pressurization

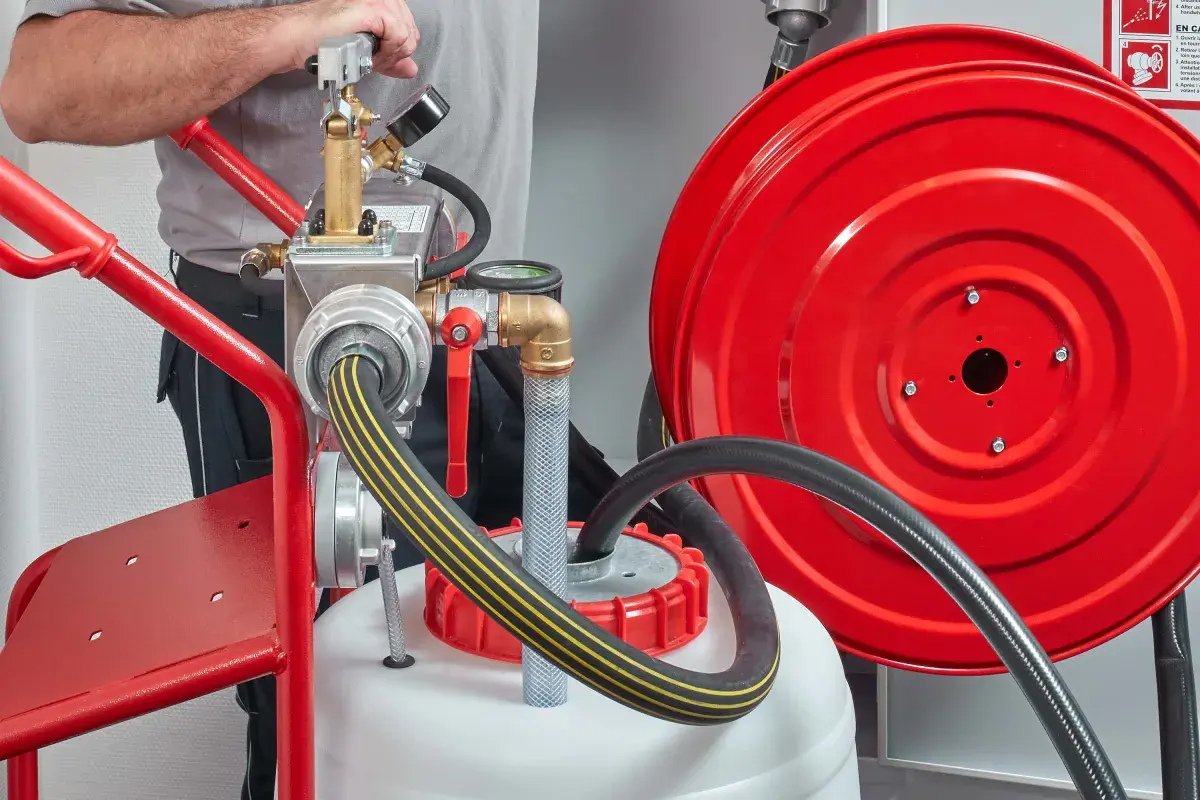

After every five years, hoses and water-carrying reels should be stressed with the highest permissible operating pressure. When measuring the pressure, a special water barrel is used where the water is collected. This keeps everything clean and dry during maintenance of the wall hydrant.

Visual inspection by operator every 6 months

A visual inspection by the operator is required at regular intervals, but at least every six months. The operator is responsible for determining the inspection intervals on the basis of a hazard analysis and findings from previous inspections.

Documentation of wall hydrant maintenance

At the end of the maintenance, our CWS service technicians seal the connection devices and stick the maintenance certificates in a clearly visible place. These labels show the inspection date and the expert number of the CWS service technician. Of course, we make sure that the wall hydrants and risers are correctly labeled.

In addition, DIN 14462 requires a maintenance report for wall hydrants. This documentation is needed, for example, for presentation to property insurers and expert inspections.

The maintenance report should include the following:

- Month and year of maintenance

- Recorded test result

- Extent and date of installation of spare parts

- Indication of whether further maintenance or repair work is required

- Month and year of next maintenance action and inspection

- Identification of each hose reel and wall hydrant

In addition to maintenance, some state building codes require a periodic inspection by an expert approved by the building authorities. For CWS Fire Safety customers, we prepare the appointment; our local and expert CWS service technician accompanies the expert. In connection with the wall hydrants, we also service additional components, for example pressure boosting systems and filling and draining stations. This service from a single source reduces effort and costs.

Reliable maintenance is a question of competence

The quality of wall hydrant maintenance is largely determined by the qualifications of the personnel performing the work: We gladly share this statement of the VdS. Maintenance, repair and testing of wall hydrants belong in the hands of qualified experts!

According to the Ordinance on Industrial Safety and Health and the Technical Rules for Industrial Safety and Health, only experts or qualified persons may perform this task. Qualified persons must be appropriately trained and experienced. Our CWS service technicians meet all the requirements.

Either way - with regular maintenance of complete wall hydrants by our CWS service technicians, you are regularly on the safe side. CWS Fire Safety is your reliable companion in all fire protection issues