Krožno gospodarstvo zmanjšuje emisije

V sodobni tekstilni industriji lahko večino emisij toplogrednih plinov pripišemo proizvodni verigi. Ta vključuje poleg pridobivanja surovin tudi postopke predelave, kot so predenje, tkanje in barvanje. S popravilom in ponovno uporabo izdelkov ter s tem njihovo daljšo uporabo je mogoče te emisije znatno zmanjšati.

Think Circular

50 % manj CO₂

Podnebna analiza potrjuje: z najemom delovnih oblačil zmanjšamo emisije CO2.

Najem delovnih oblačil namesto nakupa

Pozitiven učinek daljše življenjske dobe izdelka

Življenjska doba izdelka pomembno vpliva na vpliv na podnebje. Tu se pokaže prednost najema delovnih oblačil. Več kot je ponovne uporabe rabljenega blaga in več kot je popravil, dlje se lahko oblačila uporabljajo in manj novih oblačil je treba izdelati. In seveda vsak kos, ki ga ni treba proizvesti, ne povzroča dodatnih emisij toplogrednih plinov. Samo v Nemčiji je bilo leta 2020 v pralnicah CWS popravljenih več kot 2,5 milijona kosov delovnih oblačil.

Prednosti krožnega sistema gospodarjenja

Popravila zmanjšujejo emisije toplogrednih plinov

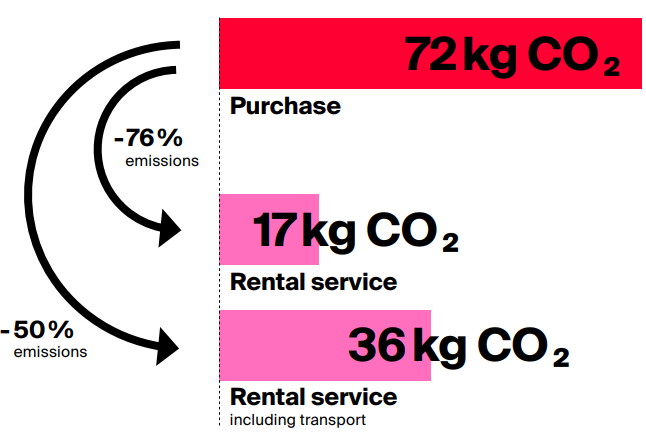

Če posameznik v Nemčiji eno leto prejema delovna oblačila prek linearnega sistema, se zaradi izdelave novih tekstilnih izdelkov, ki so za to potrebni, proizvede približno 72 kg emisij toplogrednih plinov. S popravilom obrabljenih ali poškodovanih kosov ali zamenjavo z rabljenimi oblačili se emisije toplogrednih plinov zmanjšajo na 35 kg - vključno s prevozom.